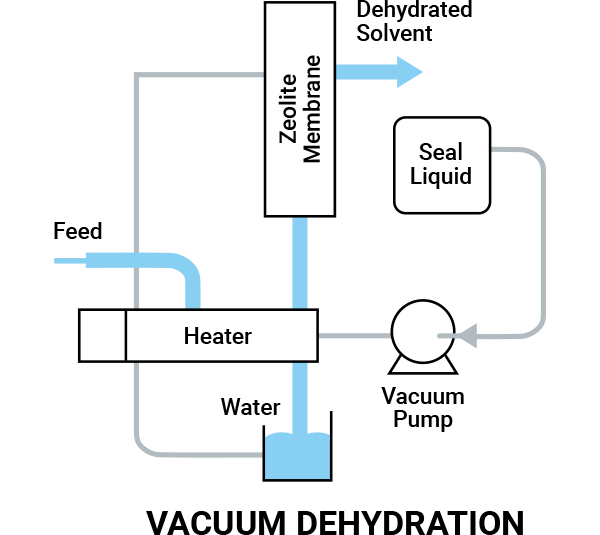

By leveraging our proprietary vacuum generation system, we can safely and

efficiently remove moisture contained in solvents.

zeolite membrane vaccum dehydorated system

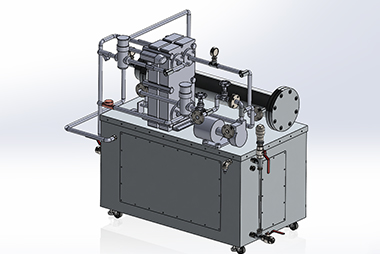

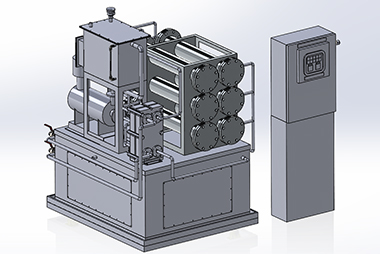

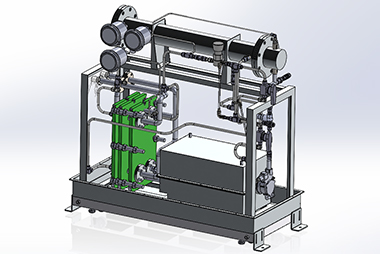

CA-500 series

Patent

Patent

Pending

After filling the built-in tank with the solvent to be dehydrated and starting the system, the solvent is pressurized and transferred using the discharge pressure of the built-in circulation pump. The heated solvent is then brought into contact with a zeolite membrane via a heat exchanger. Due to the partial pressure difference, only the water in the solvent passes through the membrane into the vacuum chamber. Afterward, the solvent is cooled by the heat exchanger and returned to the circulation tank. A moisture concentration sensor can also be installed in the circulation tank, allowing the dehydration efficiency to be monitored during operation.

CA-501(Steam)

CA-503(Heater)

CA-501(Heater)

zeolite membrane vaccum dehydorated system

CA-500 series Line Up

| Model | CA-501 | CA-502 | CA-503 | CA-504 | CA-505 | |

|---|---|---|---|---|---|---|

| Weight | 350kg | 500kg | 800kg | 1,100kg | 1,500kg | |

| Applicable Solvent | Class 1 or 2 Solvents and other | |||||

| Power Supply AC200V 3-phase Terminal Power |

Heat Pipe | Heat Pipe 14kW | Heat Pipe 26kW | Heat Pipe 65kW | Heat Pipe 90kW | Heat Pipe 120kW |

| Steam | Steam 2kW | Steam 3kW | Steam 3kW | Steam 5kW | Steam 7.5kW | |

| Optional Condenser | Optional Condenser 5.2kW | 7.0kW | 15.9kW | 25.1kW | 34.1kW | |

| Cooling Water | 0.2MPa 20℃ | 20L/min (0.2MPa 20℃) | 40L/min | 80L/min | 120L/min | 200L/min |

| Air | 0.5MPa | 300L/min (0.5MPa) | 350L/min | 400L/min | 400L/min | 400L/min |

| Steam | 0.5MPa | 20kg/Hr (0.5MPa) | 40kg/Hr | 100kg/Hr | 150kg/Hr | 200kg/Hr |

| Processing Capacity | IPA 10wt%→1wt% |

10L/Hr | 20L/Hr | 50L/Hr | 75L/Hr | 100L/Hr |

| Heating Method | Heat Pipe | Heat Pipe | Heat Pipe | Heat Pipe | Heat Pipe | |

| Steam | Steam | Steam | Steam | Steam | ||

| Heat and pressure method | heat exchanger (plate type) and back pressure valve | |||||

| Dehydration Quality | Confirmed by sample test | |||||

| Control Panel | Explosion-proof (internal pressure type) | |||||

| Pump Motor | Pressure-resistant explosion-proof | |||||

| Chiller Unit | Optional | RKE3750 | RKE5500 | RKE11000 | RKE18000 | RKE22000 |

| Condenser | Shell & Tube | |||||

※Some Class 2 petroleum products can not be distilled

Dehydration-Compatible Solvents

We can handle most hydrophilic solvents, including isopropyl alcohol, methanol, ethanol, methyl ethyl ketone, and acetone.

Depending on the solvent, we can reduce the water content to as low as 0.05 wt%.

We conduct preliminary testing to confirm feasibility.

Our system is not subject to pressure vessel regulations and comes equipped with safety interlocks. Customization is also available — feel free to contact us for details.

Contact Us

-

For those who would like to receive product

catalogs, specifications and instruction manuals -

For those who would like to hear more about our

products and quotations -

Demonstration units can be rented